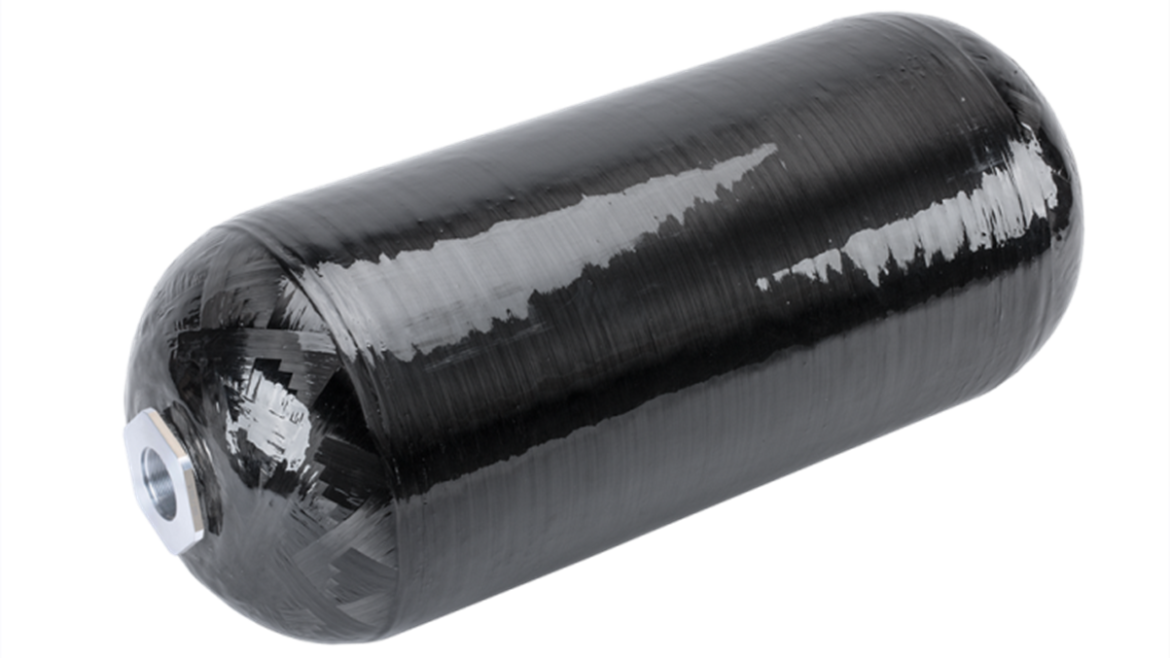

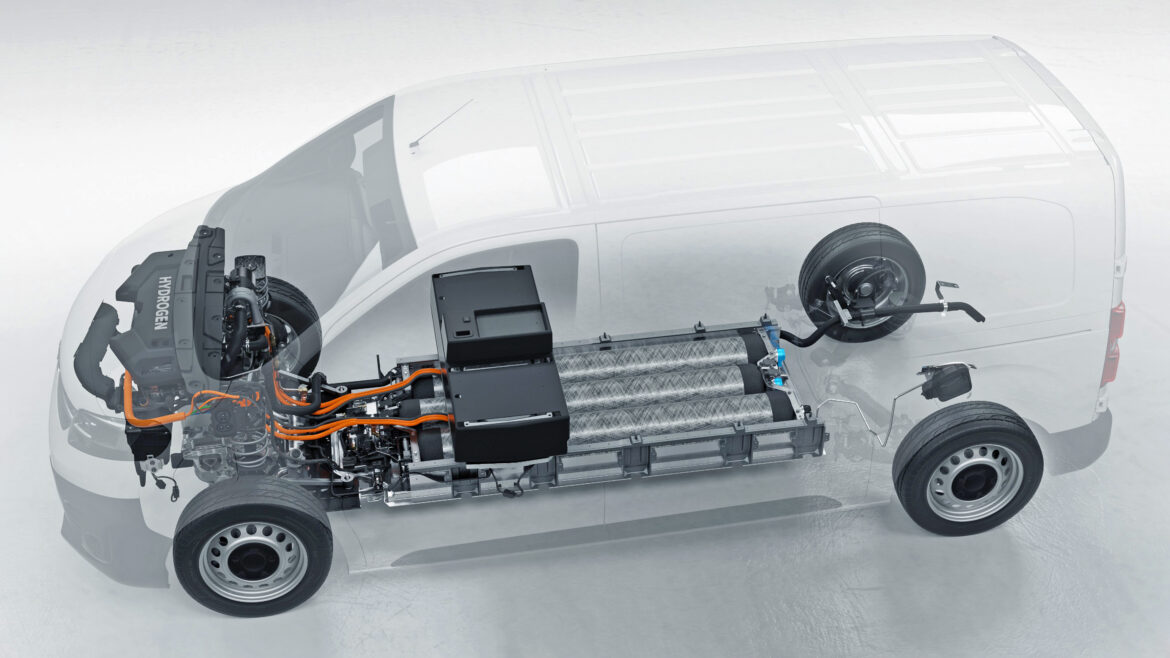

In order for the fuel cell to be used for mobile applications, it is necessary to store the required hydrogen in a mobile storage system. Hydrogen can be stored as a gas, at high pressures of up to 700 bar, as a cooled and compressed gas, or liquefied at cryogenic temperatures. For the intended use, the hydrogen storage tanks must have special properties, be it high pressure stability, high airtightness or particularly good thermal insulation.

These requirements usually mean that hydrogen tanks of the various types are particularly expensive, large, or heavy. Research and development is therefore looking at innovative materials and manufacturing processes so that tanks can in future be made lighter and more cost-effective, as well as more energy-efficient. However, the interface between the hydrogen refueling station and the vehicle is also the subject of development work, since optimized components (couplings), refueling protocols and the exchange of data (e.g. NIR interfaces) can make the refueling process safer and more effective.