Freudenberg ePower Systems has reached an important milestone in developing sustainable technologies in the maritime sector with its receipt of ‘Type Approval’ by the international classification society RINA. The methanol-operated fuel cell system makes it possible to operate ocean-going vessels in a climate-neutral way, and at the same time, efficiently and safely.

The challenge of switching commercially-run ocean-going ships to CO2-neutral drives is considerable. An important criterion is the range requirement of individual ship types. For cruise ships, tankers and container ships, they must have as long a range as possible in order to be able to cover the sizeable routes across the world’s oceans without stopping – the basic requirement is usually at least 5,000 nautical miles. Fuel cells are well suited to the task because of their high efficiency level and low maintenance requirements. Therefore it makes sense to chemically bind renewably-produced hydrogen, in order to achieve a substantially higher energy density.

Fuel cell with methanol officially certified

A methanol-powered fuel cell system by the Freudenberg ePower Systems company has now received the Type Approval from classification society RINA. This confirms the safety of the system and its compliance with maritime standards and regulations. The Type Approval was officially presented today at the leading maritime trade fair SMM in Hamburg. This constitutes an important step towards the commercial use of the fuel cell system.

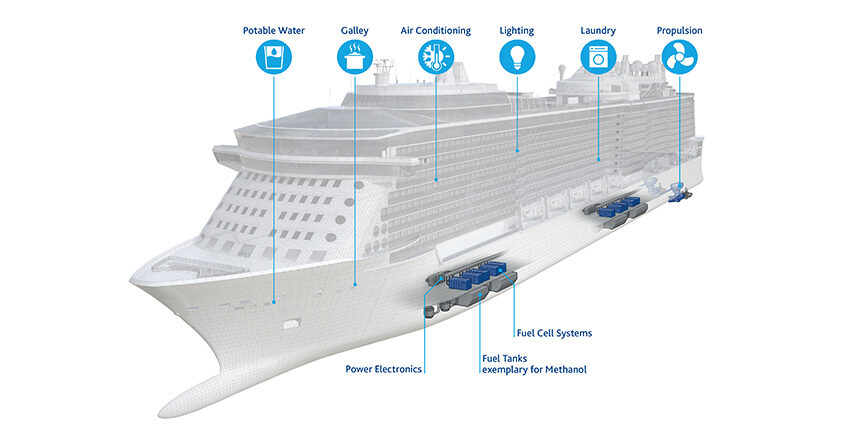

The Type Approved fuel cell system combines highly efficient fuel reforming technology with a long-life PEM fuel cell in a modular, scalable system unit. It generates hydrogen through stream reforming, which then reacts with oxygen from the air in the fuel cell, thus producing the electricity required both for propulsion as well as the onboard electrical system. The heat required for the reformer can be gained directly from the waste heat of the fuel cells. The fuel cell stack, reformer and control electronics as well as all components for media supply are found in a prefabricated, modular unit. This containment method of construction facilitates easy installation on board.

Development enabled by NIP-supported project, Pa-X-ell 2

The fuel cell system is a result of the ‘Pa-X-ell 2’ project, which is part of the federally-funded joint project, e4ships. Here leading German shipyards, shipping companies, fuel cell manufacturers and classification societies work together in the framework of the National Innovation Programme for Hydrogen and Fuel Cell Technology (NIP). The NIP is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).

Freudenberg’s safety concept was already tested for maritime conformity in an early phase in Pa-X-ell 2. It received ‘Approval in Principle’ from classification society DNV GL. In addition to the emphasis on the safety concept, the issues of modularization and standardization were examined in order to take into account the aspects of mass industrialization right from the start. In this way, system units each with a nominal output of 500 kW will be combined in the future to form an overall output in the two-figure megawatt range. Aside from Freudenberg, the renowned consortium that focusses on passenger shipping includes the partners Carnival Maritime (AIDA Cruises), Meyer Werft as well as Lürssen Werft, besecke, DLR, EPEA and the classification society DNV GL.

More about the Pa-X-ell-2 project

Press release by Freudenberg ePower Systems

Image source: Freudenberg e-Power Systems