The Chair of ‘Production Engineering of E-Mobility Components’ (PEM) at RWTH Aachen University has presented the first roadworthy prototype of a heavy-duty electric truck to be equipped with a fuel cell to extend range.

The vehicle is being developed as part of the ‘SeLv’ research project, funded by the Federal Ministry for Digital and Transport in the amount of 16.9 million euros. It was unveiled for the first time at the renowned ‘Electric mobility week’ (Woche der Elektromobilität) and at the 10th ‘Electric mobility production days’ (EPT) in Aachen. The fuel cell and the refuelling system are to be implemented in the next development phase.

The range of the e-truck is expected to exceed 1,000 kilometres in future, thanks to predictive energy management, which increases efficiency significantly. “We are taking a holistic approach to make it very easy to automatically organize entire routes, including refuelling stops and breaks, by inputting the destination”, says project manager Fabian Schmitt. “This is ensured by a networked, continually updatable system, connected to the haulage firm, providing an operating solution for driving personnel based on the ‘Android Automotive OS’ platform. Fast ‘refuelling’ keeps logistics operations running at their optimum”, says Schmitt. The project is to be continued and industrialised in future by the ‘moion GmbH’ company, which emerged from the PEM Chair. The RWTH spin-off will act in future as supplier of truck equipment and the ‘powertrain kits’ required for this.

“Electrification of heavy-duty transport is still a huge challenge for climate protection”, says PEM Director Professor Achim Kampker: While 20 per cent of all greenhouse gas emissions in Germany are attributable to the transport sector, 35 per cent of these are specifically attributable to heavy-duty and commercial vehicles. “To meet the high energy demand of heavy-duty trucks and create locally emission-free long-haul transport, we must exploit the technological advantages of the fuel cell”, emphasizes Kempker: “In addition to renewing fleets, we need to electrify the many existing vehicles as well.”

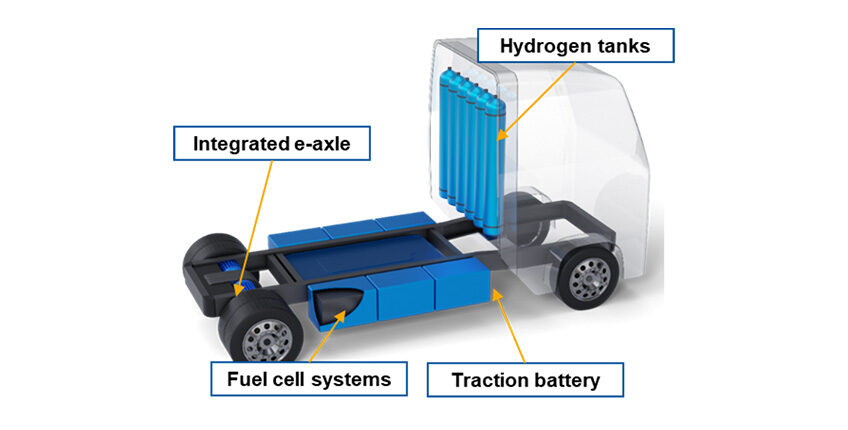

Behind the ‘SeLv’ project is the mission of ‘emission-free logistics in heavy-duty transport by means of an electrifying kit and an economic production system. The goal of the research project is to develop a modular electric drive train with fuel cell ‘range extender’ for commercial vehicles with a permitted overall weight of 41 tonnes. The drive train, which is adaptable to individual requirements, will also be equally suitable for retrofitting solutions as for new vehicles.

Further information on the ‘SeLv’ project

Image source: PEM RWTH Aachen