With the approval of a significant funding decision, Clean Logistics gains further planning security for the conversion of heavy diesel trucks to hydrogen hybrid drive. Enak Ferlemann, Parliamentary State Secretary at the Federal Ministry of Transport and Digital Infrastructure (BMVI – Bundesminister für Verkehr und digitale Infrastruktur) presented the notification amounting to funding totaling more than three million euros to the two Managing Directors of Clean Logistics, Dirk Lehmann and Dirk Graszt, in Hamburg on October 2, 2019.

The first climate-friendly converted trucks will be able to obtain road approval within a year. In the future, Clean Logistics will produce HyBat trucks with emission-free fuel cell technology and high-performance batteries as energy storage units by means of modular conversion. Clean Logistics is also part of the North German Hydrogen Network under the leadership of Michael Westhagemann, Hamburg’s Senator for Economics, Transport and Innovation.

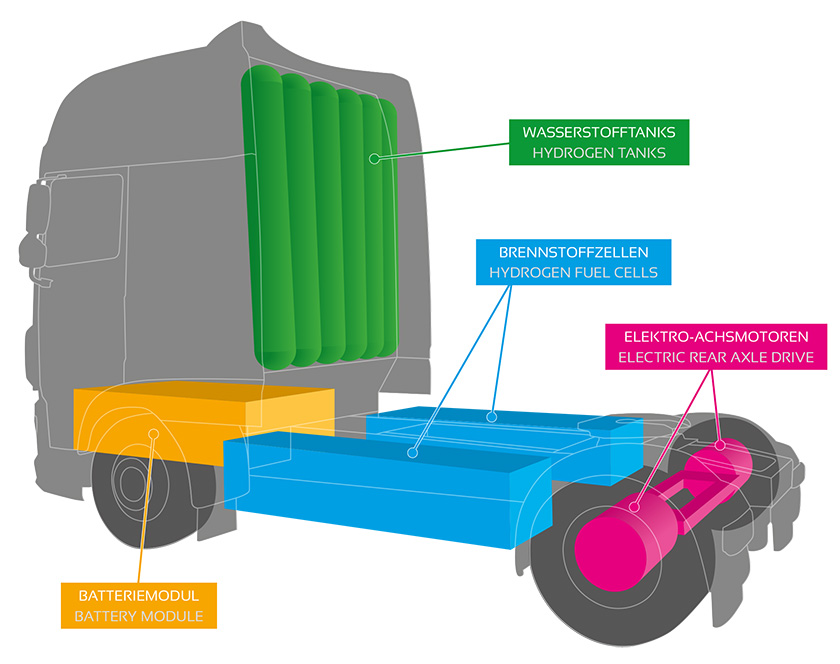

The Clean Logistics concept initially entails converting existing heavy trucks into environmentally friendly HyBat trucks. Here, the project relies on the use of the hydrogen fuel cells coupled with an electric rear axle drive. To this end, a conversion concept was developed for heavy road freight transport, which when used on the road leads to zero emissions. The modular conversion to hydrogen operation takes place after dismantling the diesel and auxiliary units of the semitrailer truck and shipping the old parts to outsourcing partners. This conversion can also be conducted by certified cooperation partners. In this way, it will be possible to handle a larger volume in the future.

The first HyBat trucks will achieve a range of 400 to 500 kilometres, based on their own hydrogen tanks that have a total capacity of 45 kilograms per truck based on H35 technology (H2 gas at 350 bar pressure). Later, depending on the chosen configuration and other customer requirements, the series production vehicles will be able to achieve a significantly higher range. In addition to the hydrogen, each HyBat truck also incorporates a powerful battery system that ensures a range of over 100 kilometres on its own.

For the production of the required hydrogen, Clean Logistics aims at a proprietary, tax-free and independent supply of H2, purely from wind energy. From the end of 2020, thousands of older wind turbines will no longer be eligible for EEG funding. In Northern Germany, this potentially means the availability of 1,500-2,500 plants for the production of hydrogen. To this end, the wind turbine is to be disconnected from the grid and a PEM electrolyser plant with a battery system is to be installed at the wind turbine to supply a wind-independent operating power supply. Wind power is then used to generate hydrogen and feed it into suitable tank trailers. These are then transported to the nearest depot and exchanged for empty trailers. HyBat trucks are then filled with hydrogen from the full trailers via a mobile refuelling facility. By renting, Clean Logistics and its partners become operators of the wind turbines, enabling the supply of hydrogen to be independent.