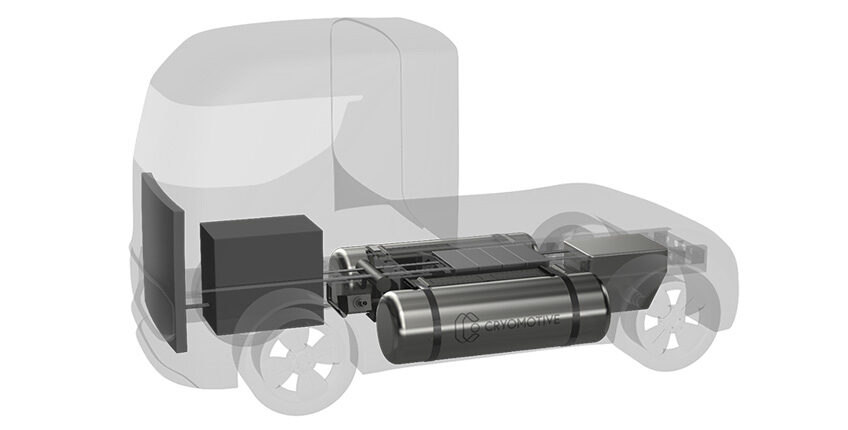

Hydrogen mobility start-up Cryomotive, commercial vehicle manufacturer MAN Truck & Bus, truck and bus retrofitter Clean Logistics, testing specialist IABG and the Technical University of Munich are jointly developing a pioneering CRYOGAS hydrogen gas tank with refuelling system for hydrogen trucks in long-distance transport.

The goal is to achieve a range of 1,000 km per single tank and refuelling in approximately 10 minutes. The CryoTRUCK consortium has received funding support from the Federal Ministry of Digital and Transport (BMDV – Bundesministerium für Digitales und Verkehr) with a starting date of 1 January 2022. This marks the commencement of the CryoTRUCK project.

Dr Volker Wissing, Federal Minister for Digital and Transport: “We want to move towards zero-emission logistics on the road with alternative drives systems and fuels. Around 90 percent of all carbon emissions in the transport sector come from road traffic, with trucks accounting for a third of this. The development and testing of hydrogen gas tanks and refuelling systems for fuel cell trucks in long-distance transport are a positive and important step towards more climate protection in transport. I am very excited about the results the consortium will achieve in terms of refuelling time and range.”

The three-and-a-half-year CryoTRUCK project, which has a total budget of more than €25 million, will focus on developing and validating a first-generation technology for a cryogenic compressed hydrogen gas (CRYOGAS) storage and refuelling system in heavy-duty fuel cell trucks.

Using low-cost, compact and lightweight CRYOGAS onboard storage technology and a newly designed energy-efficient rapid refuelling system for “cryogenic” hydrogen gas, future long-range hydrogen trucks will be able to achieve a range of 1,000 km with a single refuelling procedure and will be able to refill with hydrogen in 10 minutes. CRYOGAS, a cryogenic pressurised gas possessing a very high density, can be produced from either liquid or gaseous hydrogen. The CRYOGAS technology can thus build on existing gaseous hydrogen infrastructure as well as use newly emerging liquid hydrogen infrastructure for commercial vehicles.

Kurt-Christoph von Knobelsdorff, Managing Director of NOW GmbH: “Fuel cell trucks are a major building block in the technology-open ‘Overall Concept for Climate-Friendly Commercial Vehicles’ [‘Gesamtkonzept Klimafreundliche Nutzfahrzeuge’]. The refuelling technology is a key issue for the development of the necessary refuelling infrastructure for hydrogen commercial vehicles – which is one of the reasons why this project is of major importance.”

The CryoTRUCK consortium brings together leading expertise in hydrogen tank and refuelling, testing and commercial vehicles. Hydrogen mobility start-up Cryomotive provides the development and manufacturing expertise for cryogenic hydrogen refuelling technology in the project. Leading commercial vehicle manufacturer MAN Truck & Bus and the fast-growing fuel cell truck and bus retrofitter Clean Logistics, which converts existing trucks from diesel to hydrogen power, are contributing expertise in integration and testing for the truck test vehicles. IABG possesses the knowledge and experience needed for testing the tank and refuelling technology. The three academic chairs of the Technical University of Munich are proviproviding support with know-how in the areas of modelling and simulation, concept development, carbon fibre composite material and manufacturing technology, and metal forming technology.

The CryoTRUCK consortium has received confirmation from the Federal Ministry of Digital and Transport (BMDV) of its intention to fund the project, which was launched at the beginning of 2022. In 2024, the CryoTRUCK consortium will test and subsequently integrate the CRYOGAS hydrogen tank systems with a hydrogen storage capacity of 80 kg, which corresponds to an energy content of more than 2,600 kWh, in two test vehicles with different configurations and drive systems. The storage system will be refuelled at a first test filling station with the help of a newly developed CRYOGAS refuelling system. The aim of the project is to prove the suitability of the CRYOGAS technology for use in long-distance commercial vehicles.

The CryoTRUCK consortium

Cryomotive was founded in 2020 to develop high-density, high-capacity hydrogen refuelling technology with the aim of bringing it to market maturity from 2025. One of the main areas of development is the cryogenic pressurised hydrogen storage CRYOGAS, which has already been successfully developed and demonstrated for use in passenger cars in a preliminary stage as CcH2 “cryogenic pressurised gas storage” under the leadership of one of Cryomotive’s founders at BMW. Cryomotive’s CRYOGAS hydrogen technology, which has been further developed for long-distance applications in commercial vehicles, offers the potential to enable a range of 1,000 km and a refuelling time of 10 minutes in heavy-duty long-distance commercial vehicles and furthermore to be combined with additional performance and flexibility advantages for the vehicle drive and the refuelling station infrastructure. As part of the CryoTRUCK project, Cryomotive will develop a CRYOGAS hydrogen storage system and its core components and test them together with the two truck partners MAN Truck and Bus as well as Clean Logistics. In addition, Cryomotive and its partners will prepare a CRYOGAS test fuelling station with a newly developed CRYOGAS fuelling system for trial operation.

MAN Truck & Bus is one of the leading European commercial vehicle manufacturers and providers of transport solutions. Its product portfolio includes vans, trucks, buses, diesel and gas engines, as well as services related to passenger and freight transport. With its expertise in alternative fuels and drives, MAN is providing support in the CryoTRUCK project in the design and dimensioning of the storage system and in defining the interfaces for vehicle integration. A fuel cell truck will serve as the platform for integrating the system. Following the installation of the storage system, the fuel cell truck will be intensively tested in terms of performance, efficiency and handling.

The listed company, Clean Logistics SE (WKN/German securities identification code: A1YDAZ), is considered one of the technology leaders in the decarbonisation of the transport sector. By using modern hydrogen technology in combination with battery storage, buses and tractor units are made fit for the future. Clean Logistics replaces the conventional diesel drive in existing vehicles with emission-free drive technology and innovative operating technology. With such conversions, Clean Logistics is leading local and heavy-duty public transport towards a climate-neutral future, thus making a significant contribution to achieving the national climate targets. In the CryoTRUCK project, Clean Logistics is responsible for integrating and testing a hydrogen fuel cell drive with CRYOGAS storage in a diesel truck converted by Clean Logistics.

As a leading testing expert, IABG is responsible for the development and first-time implementation of new test procedures to validate the CRYOGAS storage and refuelling technology. The focus is on component and system testing with cryogenic compressed gas and the qualification of hydraulic test procedures for storage systems. IABG will actively contribute to the realisation of this project with its expertise and testing capabilities. As part of this important project for the development of emission-free technologies, IABG will comprehensively expand its testing capacities in the field of hydrogen storage.

Three institutes of the Technical University of Munich (TUM – Technische Universität München), including the Chair of Plant and Process Engineering (APT – Lehrstuhl für Anlagen- und Prozesstechnik), the Chair of Carbon Composites (LCC – Lehrstuhl für Carbon Composites) and the Chair of Forming Technology and Foundry Engineering (UTG – Lehrstuhl für Umformtechnik und Gießereiwesen), will focus their research support on thermodynamic modelling, the evaluation of storage and refuelling station concepts and the further development of carbon fibre reinforcement and liner production.

Image: Clean Logistics SE