Personal transport must keep up with the necessary changes: Citizens are acquiring the latest cars with the new drive systems – in good time and in sufficient numbers – and the government is providing subsidies to ensure that they can also refuel and recharge them. Cities and municipalities are also increasingly updating their fleets, and are being supported both financially and with know-how. After all, climate change won’t wait.

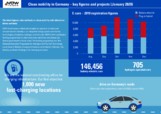

To achieve the climate targets set, Germany needs 10 million zero-emission vehicles on its roads by 2030. The first necessary prerequisites for the refuelling and charging infrastructure will be in place by 2020. With the 100 hydrogen filling stations then in place and at least 36,000 standard and 7,000 fast charging points publicly accessible, mobility with alternative fuels and drive systems will be possible for a large number of people across the country. Not least thanks to the support provided by the corresponding programmes of the German government, a new record has recently been reached in the number of new registrations of electric passenger cars.

With its local electric mobility (“Elektromobilität vor Ort”) funding programme, the Federal Ministry of Transport and Digital Infrastructure (BMVI) supports cooperation between industry, science and the public sector in order to promote the further market ramp-up and the embedding of electric mobility in everyday life. In addition, BMVI and the Federal Ministry for Economic Affairs and Energy (BMWi) are investing in emission-free mobility with hydrogen and fuel cells in the National Innovation Programme Hydrogen and Fuel Cell Technology (NIP2).

Picture Gallery

Publications

Buses – always admirable how these lengthy beasts get around tight curves. And now they must tackle the mobility transition. Public transport companies are converting their fleets to electric. Pilot projects have verified the feasibility; different drive technologies are available. The municipalities and companies can use the networks coordinated by NOW GmbH to exchange information and ideas.

Nitrogen dioxide and carbon dioxide emissions, noise, particulate matter – the energy transition in transport also poses challenges for local public transport, whether road or rail. Some public transport companies are equipping themselves for the future and are now undertaking the conversion of their fleets to vehicles with alternative drives. Batteries and fuel cells are the focus, the advantages of which can be demonstrated when electricity or hydrogen is used from renewable energies.

City Buses: A Question of Drive

Public buses cover distances of between 200 and 400 km per day. In the process they brake and accelerate much more often than trucks. With a scheduled service life of twelve years and 750,000 kilometres driven, the vehicles must be robust and at the same time as comfortable as possible. Over ten million test kilometres from pilot projects show that it is technically possible to operate the majority of public buses electrically by the year 2030. There are currently a variety of drive technologies available for operation.

Battery Buses

A guaranteed range of 200 km is enough for many bus operators for the first conversion of entire routes to battery buses. The first available vehicles on the market cover these daily distances. This enables uninterrupted driving operation, with recharging taking place at night at the depot. Charging is also possible during operation. Here the bus charges via inductive or conductive fast-charging at bus stops or turn-backs or through a partial overhead line. The required battery capacity and the downtime are thus considerably reduced.

Fuel Cell Buses

For longer routes, hydrogen-operated buses are a good alternative to batteries. In around ten minutes, the buses refuel enough hydrogen for 300-400 kilometres of driving. Fuel cell buses thus bring a flexibility which is comparable to a diesel bus and can be easily integrated in the operational procedures of transport companies. Alternatively a battery bus can be equipped with a fuel cell as a range extender. Here both drive technologies complement one another: a battery provides energy for the drive, absorbs this when braking and is recharged during breaks or at the depot. During the journey the battery is recharged by a smaller fuel cell.

A rather large volume of greenhouse gases is produced by a rather small number of vehicles: trucks. Whether overhead line, battery or hydrogen trucks or vehicles with liquid gas drives, many things are conceivable and have already been or are being tested in pilot projects to promote the energy transition – in trucks. With scientific support, so development proceeds in the best direction.

Road freight transport accounts for a significant overall share of GHG emissions from transport and is expected to increase further in the coming years. The transport forecast for 2030 assumes a growth of 38 percent in freight transport. At the same time, the number of vehicles responsible for GHG emissions is comparatively modest compared to the number of registered passenger cars. This means that considerable potential GHG reductions can be achieved by converting a relatively small number of vehicles to low-emission drives in road freight transport.

To date, however, only very few vehicles with alternative drive systems are available, especially for long-distance transport. In particular, semitrailer trucks with liquefied natural gas (LNG) drives are available on the market and are increasing their market shares due to the currently available funding possibilities. In this context, the BMVI supported the pilot project for the procurement and testing of 20 LNG trucks at Meyer Logistik in the Berlin region at an early stage as part of the Mobility and Fuels Strategy (MFS), in order to gain insights for initial market entry. The results of the project, which was successfully conducted in 2017, show that depending on the load, route and operating area, the emission reduction figures cited in the relevant literature can indeed be achieved.

In the medium term, hydrogen and catenary trucks are also seen as an option for heavy road transport. In order to validate the findings of existing studies within the scope of the MFS, the implementation of support measures in other NOW-coordinated programmes and also the initiative for climate-friendly road freight transport, it is important to initiate pilot projects for emission-free long-distance heavy goods transport. A significant focus of future measures for these technologies should be on the necessary infrastructure.

Everyone knows forklifts, but there are countless other types of special vehicles for various applications. Stricter environmental regulations bring new challenges, and climate-friendly drive technologies have become an economic factor. Last but not least, alternative drives serve to protect the health of the workforce.

Alternative drive technologies are also the focus in the logistics sector. Stricter environmental directives bring new challenges and climate-friendly alternatives are becoming an economic factor. One way of anchoring sustainability in the logistics sector is the use of vehicles with fuel cell technology that use hydrogen as a fuel. From forklifts in the warehouse to luggage tow trucks at the airport – in intralogistics they provide a good opportunity to lower energy consumption as well as pollutant and CO2 emissions and avoid noise. Policy-makers see great potential in this for climate protection and are offering relevant funding opportunities.

Commitment for the future: CIN

An important player on the path to the extensive use of the hydrogen drive is the industry network Clean Intralogistics Net (CIN). The collaboration of now thirteen renowned and globally-operating companies has committed itself to one main goal: to make the transport and handling of goods in industry, trade and at airports emission-free, more efficient and also more profitable. Using the joint network, the partners want to advance using fuel cell-operated fork lifts and haulers – so-called ground conveyors – as well as vehicles on the airport tarmac. They also plan the associated hydrogen infrastructure along with it. Exchanging experiences and knowledge transfer is at the forefront for the network, so that individual projects can be bundled and to help the climate-friendly type of drive to breakthrough point. The CIN also receives expert support in this from associated partner, VDMA (The Materials Handling and Intralogistics Association).