As part of the ‘TiKaBe’project network, Fraunhofer ISE is developing innovative catalyst inks that can be used for various industrial coating processes. Shortening and simplifying the so-called ‘break-in’, or the initial conditioning of fuel cells, is the focus of the research project: ‘BI-FIT’.

Through the ‘BI-FIT’ (Break-In for Fuel Cells Initializing and Testing) and ‘TiKaBe’ (Inks development for fuel cell catalyst coating – Tintenentwicklung für die Brennstoffzellen-Katalysatorbeschichtung) projects, researchers at the Fraunhofer Institute for Solar Energy Systems ISE are optimizing the large-scale production of proton exchange membrane (PEM) fuel cells. The projects are funded under the National Innovation Programme for Hydrogen and Fuel Cell Technology with a total of 1,015,210 euros and 1,344,738 euros respectively by the Federal Ministry for Digital and Transport. The funding guideline is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).

High demand is expected in the near future for fuel cells for electric drives, particularly for global heavy-duty transport. The market ramp-up of PEM fuel cell technology therefore requires innovative concepts for the industrial manufacture of the membrane electrode assembly (MEA), which facilitates large quantities to be produced, while simultaneously being resource- and cost-efficient. Fraunhofer ISE, together with its project partners, is creating the technological basis for this for the f-cell automotive and supply industry.

Scientists from Fraunhofer ISE are to provide current insights into this research as part of the hy-fcell conference programme, held on 13 & 14 September in Stuttgart. At stand 4D55, the institute will exhibit membrane electrode assemblies (MEAs) for heavy-duty applications and describe the characterization of cell components and life cycle tests.

Novel catalyst inks for different coating processes

At Fraunhofer ISE, new types of catalyst inks with shorter drying times are being developed for various industrial coating processes in the TiKaBe project (Inks development for fuel cell catalyst coating). “We are developing long-lasting membrane electrode assemblies with low levels of precious metals for this purpose”, explained Ulf Groos, Head of Fuel Cells Department for the Hydrogen Technologies Division. “We are looking at the so-called ‘slot die coating’, which because of its very homogenous, continuous coating capability, is predestined for industrial processes. In future, printing processes such as inkjet, engraving and screen printing will become interesting, because they make structured layers possible and therefore minimize waste and material losses through printing a defined catalyst area.”, added Groos.

Optimised commissioning of the fuel cell stacks

In the project: ‘Break-In for Fuel Cells Initializing and Testing’ (BI-FIT), Fraunhofer ISE scientists are gaining a fundamental understanding of the decisive mechanisms involved in the initial conditioning of fuel cells. Break-in or initial conditioning is the name of the process by which a newly produced fuel cell stack is powered with electricity for the first time, in order to expand its nominal capacity and ensure a homogenous individual cell voltage. Because of the long duration of the process, the break-in currently still represents a substantial bottleneck and a major cost consideration in the manufacturing process of fuel cell production. Current break-in methods require between two and eight hours to fully activate a fuel cell stack. In mass production of fuel cell stacks, this accounts for around 5 per cent of total manufacturing costs.

The aim of the research is to shorten and simplify the break-in through innovative concepts to a maximum of 60 minutes and one per cent of the overall manufacturing costs respectively. The interrelationships between the production of the crucial component of the membrane electrode assembly, stack design and operating conditions during the break-in must be taken into consideration and optimally coordinated.

Further information:

www.ise.fraunhofer.de/de/forschungsprojekte/tikabe.html

www.ise.fraunhofer.de/de/forschungsprojekte/bi-fit.html

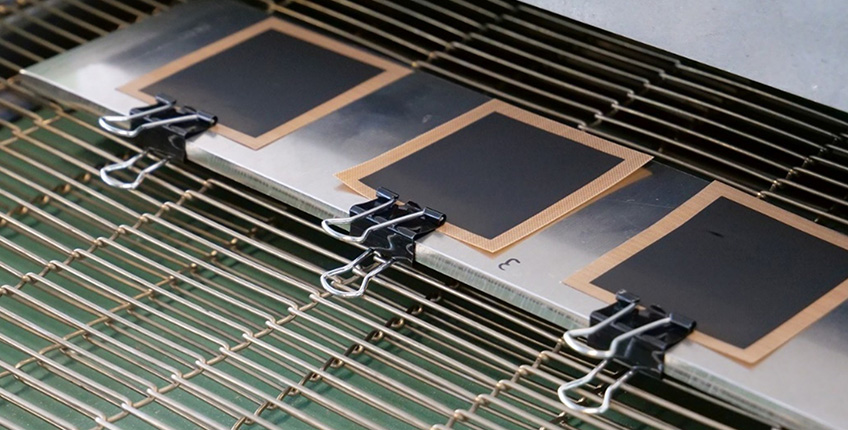

Image: Scientists from Fraunhofer ISE work on the optimisation of proton exchange membrane (PEM) fuel cells. © Fraunhofer ISE

Source of original release: Fraunhofer ISE