Innovation boost for SOFC fuel cells at sea

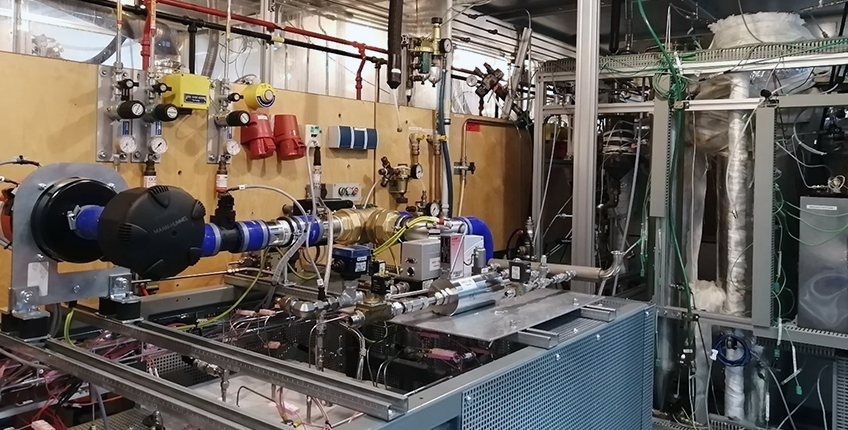

The MultiSchiBZ research project has come to a successful conclusion with an innovation boost for the use of fuel cells in maritime shipping. Over the past two years, OWI Science for Fuels gGmbH has set up and operated a solid oxide fuel cell (SOFC) system in the laboratory. It is designed for the production of on-board power for ships operating at sea and at berth in ports. The system is designed to convert liquid fuels that are available on board into a hydrogen-rich fuel gas, which SOFC fuel cells convert into electrical energy. Operation of the system is low in carbon dioxide and other pollutant emissions, as well as being quiet and virtually vibration-free.

Prototypes of new types of SOFC fuel cell modules are used for the set-up of the demonstrators in laboratory operation, with a total output of 25 kWel. These are integrated into an overall system consisting of a process gas module, an afterburner for hot exhaust gas and a DC-AC converter. The process gas module converts liquid fuel into a hydrogen-rich fuel gas which is used to operate the fuel cell module. During the tests on the overall system demonstrator, the researchers evaluated the operating points, load changes and starting behaviour. The emission values are significantly lower than those of conventional motor units.

The development of the process gas module took a giant leap towards achieving technological maturity. A central element of the module is the catalytic converter installed in it, whose service life has a major influence on the economic efficiency of the overall system. With optimised process strategies, for example with regard to the temperature and the mixing ratio of water, as well as the combination with sulphur-free synthetic and biogenic fuels, an increased service life of the catalyst of more than 10,000 h can be realised. This also makes economical maintenance concepts achievable. Furthermore, it has been possible to successfully achieve a closed-loop system for the process water by condensing the water and treating it for use in the cycle.

New development: Passive anode exhaust gas recirculation

The hot residual anode gas from the fuel cells remains in the system for further use. Part of the residual gas is converted into thermal energy in the afterburner, which is then used to provide the process steam in the steam reforming unit via a high-temperature heat exchanger. OWI has developed a completely new technology to utilise the remaining residual gas: passive anode gas recirculation. In this way, hydrogen-containing residual gas particles remain in the system and can be further utilised. Residual gas recirculation with hot gas blowers is the state-of-the-art in SOFC fuel cell systems, but they are expensive, prone to failure and reduce the overall system efficiency. Passive anode gas recirculation serves the same purpose as a blower, but functions via a blasting jet of hot steam. OWI developed the component with the help of numerical simulations (CFD). It was manufactured using the 3D metal printing process, which enables the production of compact devices requiring significantly less space in the system. Material tests conducted by OWI confirm the comparability of additive manufacturing with conventionally manufactured components. A proof of concept shows the functionality of recirculation for all operating points, start-up and varying loads.

Key to the success of the project was a thorough knowledge of the complex systems and smart manufacturing processes for compact components with high power density. The upscaling of the laboratory demonstrator for the implementation of a larger overall system demonstrator with an output of 300 kWel has already taken place. Its implementation is the goal of an intended follow-on project. The partners in the MultiSchIBZ consortium led by OWI Science for Fuels gGmbH were DNV, Hülsenbusch Apparatebau, Institute of Thermodynamics at Leibniz Universität Hannover, Institute of Electrical Energy Systems at Leibniz Universität Hannover, Rosswag Engineering, Sunfire, Tec4Fuels and the Centre for Fuel Cell Technology.

MultiSchIBZ was one of the lighthouse projects of the e4ships research cluster for sustainable shipping of the future. It was funded by the Federal Ministry of Digital and Transport (Bundesministerium für Digital and Transport) within the scope of the National Innovation Programme Hydrogen and Fuel Cell Technology with a total of 7,163,422 euros. The funding guideline is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).

Further information is available online at: www.owi-aachen.de

Image: The test stand with the MultiSchiBZ solid oxide fuel cell (SOFC) system in the OWI laboratory | Image source: OWI