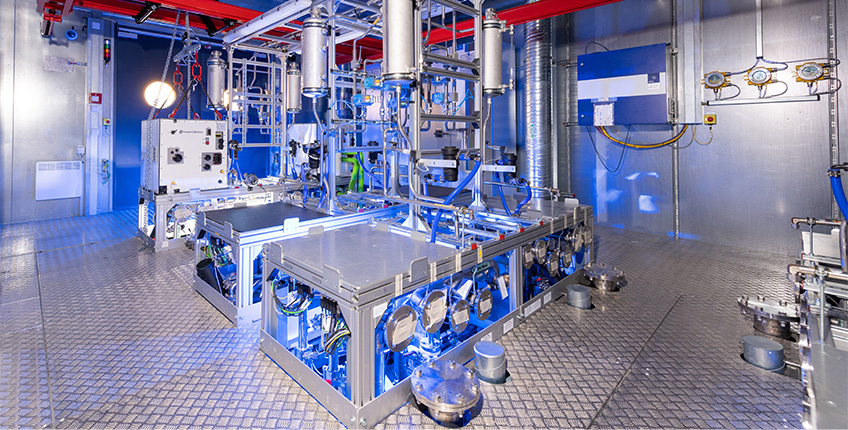

With the BALIS project, the German Aerospace Centre (Deutsche Zentrum für Luft- und Raumfahrt (DLR)) is building a unique scientific test facility in order to develop and test the components of fuel cell-based electric drives for mobile applications with an output of up to 1.5 megawatts. For the first time, researchers were able to reach an output of more than one megawatt with two of the most important components – the fuel cells and the electric motor.

“This is an important milestone in building and commissioning the test facility and the first generation of the fuel cell test system”, explains project manager Dr. Cornelia Bänsch from the DLR Institute of Engineering Thermodynamics. Systems of this performance class are not yet available on the market. The technical challenge lies in developing and bringing together all components in such a manner that they run in a stable way at a high output of one megawatt or more. For this purpose, DLR researchers are coupling a total of twelve fuel cell modules electrically. All modules exchange information and interact with each other. Each of these modules in turn consists of more than 400 individual fuel cells.

“We are developing sophisticated operating strategies in order to manage this complex structure. We want to gradually increase the stable operating time of the test system and heighten the output to over one megawatt. As soon as it works, we will also run dynamic profiles. This includes operation at different, high outputs for varying lengths of time, in other words, conditions that might arise in practical application”, summarises DLR researcher Bänsch.

The research is being carried out as part of the BALIS 2.0 project under the National Innovation Programme for Hydrogen and Fuel Cell Technology, funded with a total of 9.3 million euros by the Federal Ministry for Transport (BMV). Funding for this measure is also provided under the German Recovery and Resilience Plan (DARP) through the European Recovery and Resilience Facility (ARF) in the NextGenerationEU program. The funding guideline is coordinated by NOW GmbH and implemented by Project Manager Jülich (PtJ).

Fuel cell systems, such as those developed and tested by DLR with BALIS, could in future be used for example to power ships, for heavy-duty road transport or for aviation. If hydrogen from renewable sources is used in the fuel cells – so-called green hydrogen – they enable CO2-free and therefore climate- and environmentally-friendly mobility. At the same time, this technology enables us to become less dependent on fossil raw materials and to strengthen the robustness of innovation and competitiveness of German industry in the high-tech sector.

The complex and modular BALIS test field enables individual components and also entire drive trains – for example together with aviation research institutes in terms of propulsion – to be comprehensively examined. Because of its size, flexible structure and the associated research methodology, the facility is unique worldwide. It is located on the innovation campus of the E2U Empfingen Development Centre for Environmental Technology.

You can find further information here: BALIS test system components cross megawatt threshold for the first time

Photos: DLR

Source: www.dlr.de/de